Twenty years ago, the Policy Commission on the Future of Farming and Food advocated a rethink on food waste. The 2001 report spoke of 200,000 tonnes per year of compostable material generated by supermarkets ending up in landfill. The progress since in the reduction and elimination of waste has been remarkable, often led by meat processing companies.

The government launched its policy on waste in 2018 with the aim to reduce food waste by half by 2030. This worthwhile goal will contribute effectively in reducing the environmental impact of food production but also in feeding the 8.4 million food-insecure people living in this country. For instance, eliminating food would lower by 6% the national water footprint according to the Waste and Resources Action Programme (WRAP). The task is immense as the UK wastes 10 million tonnes of food and drink per year and logistical difficulties abound. Meanwhile, the Scottish government aims to reduce food waste by a third between 2013 and 2025, leading to reduction of 1.5% of Scottish total carbon impact. The inaugural Food Waste Action Week took place in March this year highlighting the need for action.

Efforts are starting to pay off with the volume of food waste falling by 7% since 2018 and the disposal of food or by-products in landfills - leading to the production of methane, broadly eliminated. Still, progress in reducing food waste in households is slow. For example, only 58% of people know that chicken can be frozen up until the Use By date according to WRAP. Households wasted less food during the Covid-19 pandemic as they had more time more meal planning.

Despite the strong record of Wales in the management of food waste, international comparisons are not always flattering: there are only 372 anaerobic digesters to recycle food and agricultural waste in the UK against 10,000 in Germany.

On the positive side, the amount of food distributed to charities has doubled between 2015 and 2019, reaching 55,000 tonnes. The aid organisation Fare Share plays a leading role and distributes 7% of surplus food available in the UK from retailers and food processors to numerous charities. Meat companies such as Higgidy Pies and Richmond Sausages have contributed to the campaign with products; Cranswick runs an important initiative in the Hull area, redistributing surplus food.

£3 billion worth of meat waste to be halved.

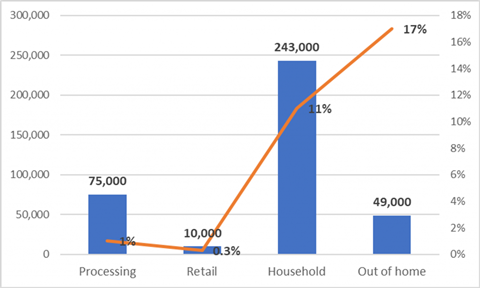

The commitment of British meat processors to WRAP’s Food Waste Reduction Roadmap is truly outstanding with no less than 19 operators signing the pledge, including some medium-size companies such as Beckett’s and Linden Foods. Most importantly, in 2020, some 40 UK organisations, individual processors, retailers and food service companies have pledged to halve the 400,000 tonnes of meat wasted in the chain, worth £3 billion, some 75,000 tonnes of which occurring during processing [66% poultry, 27% beef, 6% pork, 1% sheep meat].

As shown in the graph below, although the volume of meat wasted or lost during processing represents a sizeable and worthwhile target, most losses occur in households or restaurants rather than in factories, supermarkets or butcher shops. In a comprehensive Swedish study, the meat department of supermarkets contributed 3.5% of the overall wasted food mass. One must keep in mind that meat ranks a long way down the priority list regarding waste when compared to other commodities such as potatoes, fruits and vegetables.

Meat wasted or lost in the supply chain (%, tonnes)

Campden BRI is looking for partners to help with new research that aims to revise established shelf-life standards in order to improve the sustainability of red meat products. It could save producers and retailers money in wasted food by updating specifications to reflect current meat processes. Microbiologist Greg Jones, who is leading the project, says: “Our new project will investigate whether existing standards for assessing shelf-life are in line with today’s production practices for red meats. We’ll be undertaking microbiological and sensory testing to see if we can set more realistic standards, making this food more sustainable and potentially increasing shelf-life without compromising product safety.”

British meat processors are taking their responsibility on food seriously, are setting tough targets for reductions, are investing resources and are reporting on progress. However, they could be more vocal on their successes as many large food corporations do – these are every so often keen to malign meat business without showing the same level of achievement! Notwithstanding the positive developments in large businesses, medium-size companies are at considerable disadvantage due to their more limited resources. Still, the sector as whole can be proud of its progress so far.

This story was originally published on a previous version of the Meat Management website and so there may be some missing images and formatting issues.